Products

Metallographic Equipment

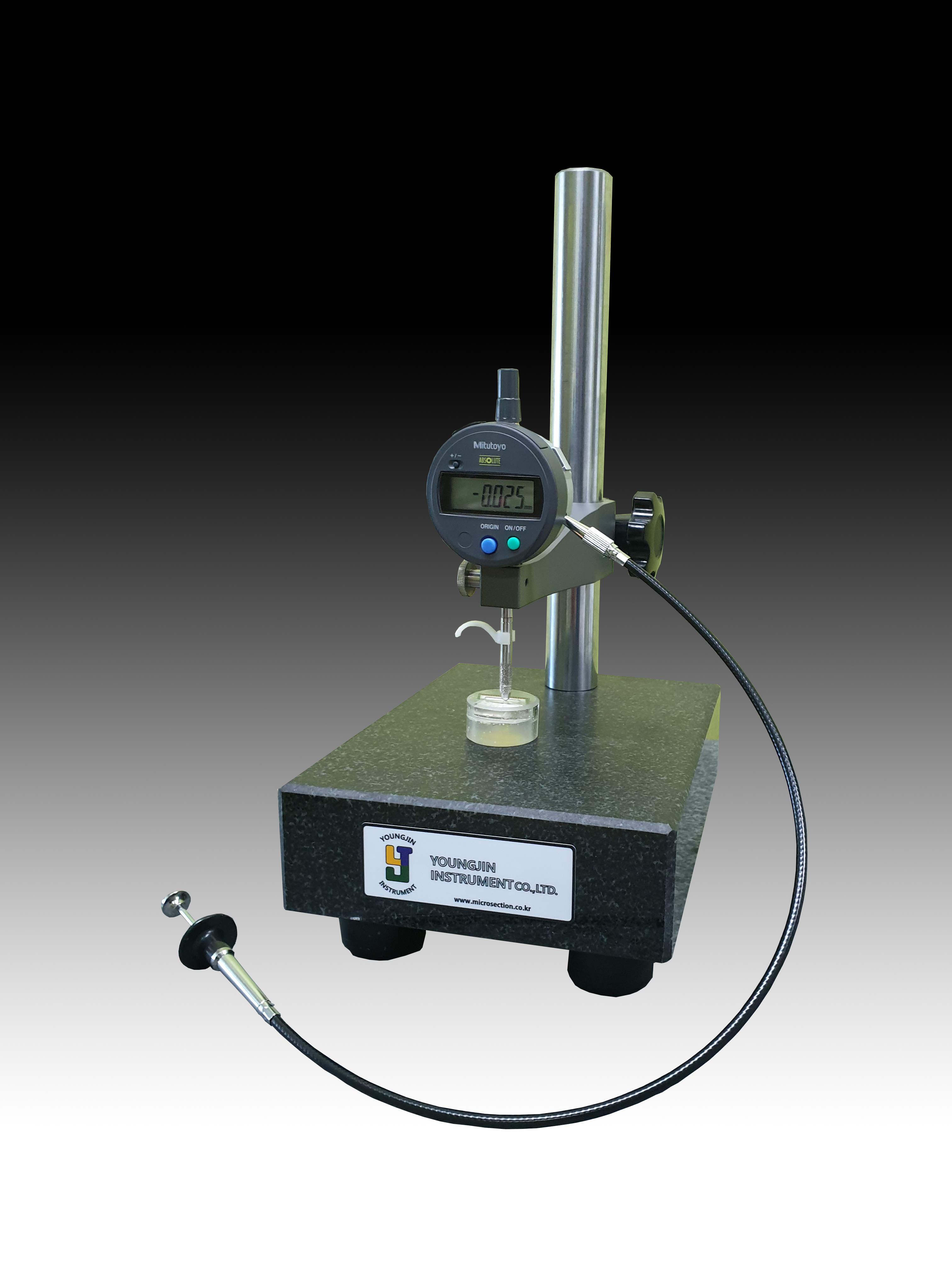

Grinding Gauge

Grinding Gauge

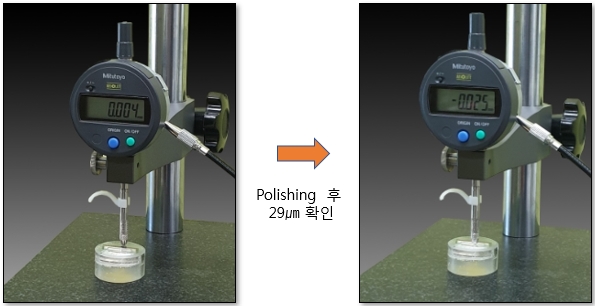

If the observation point can be clearly recognized with the naked eye during microsection for cross-sectional observation of the sample, it can be checked during the Grinding & Polishing stage. However, if it is difficult to directly identify the sample due to the material, shape, size, or other factors, the desired measurement point can be implemented by comparing the height of the sample after the grinding and polishing step.

When the gauge is directly operated during sample measurement, the gauge may be affected by force, but the impact was minimized by using auxiliary lifting options.

| A | B | C | D | |

|---|---|---|---|---|

| Resolution | 0.0001 | |||

| Accuracy | 0.003mm | 0.005mm | ||

| Max Range | 12.7mm | 25.4mm | 50.8mm | |

| Measuring Force | 1.5N or less | 0.4~0.7N | 1.8N or less | 2.3N or less |

| Stem diameter | 8mm(ISO/JIS Type) | |||

| Battery | SR44, 938882 | |||

| Battery Life | 7000hours | |||

| Dustproof/waterproof | IP42 | |||

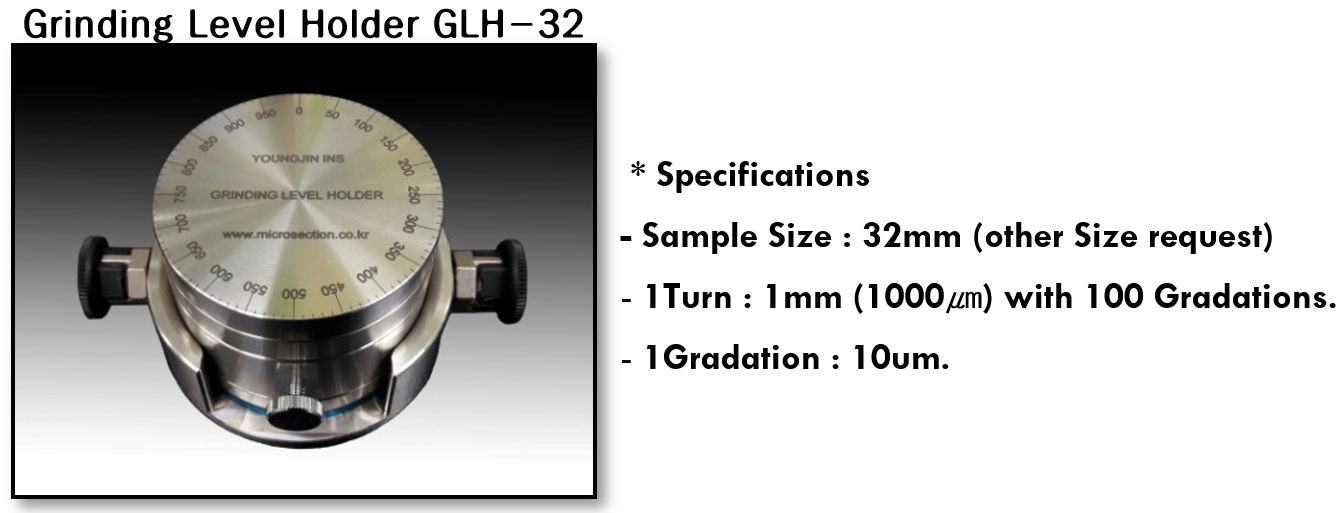

If one-sided wear occurs during grinding and polishing work, deviation according to location may occur, which may also affect measurement results. It can also be a good direction to use a Grinding Level Holder that can reduce one-sided wear that may occur during work and adjust the desired depth of work.