Products

Giới thiệu sản phẩm

Elec-Beam Machinery

CP-8000+

The CP-8000+ is an equipment that uses argon ion beams to etch the cross section of a sample, and it does not cause physical deformation such as structural damage to the cross section and does not require chemical processes,

so it can be treated cleanly without complicated processes. In addition, it is easy to analyze the sample cross-section by processing a larger area from dozens of um to mm.

- High etch rate of 700 μm per hour (based on Si, 8 kV)

- Save/Import frequently used recipes

- Step by step recipe automatic execution function

- Easy sample loading using sample height jig and smart sample holder

- Observe ion beam status, etch status in real time (chamber camera)

- Convenient Screenplay - Intuitive GUI and easy touch screen

- Minimize heat damage with ion beam Auto On/Off function

- Fast and convenient ion beam-sample alignment using digital microscopes

- Noise, vibration, oil-free diaphragm pump base provided

- Built-in Flet milling for plane etching over large areas

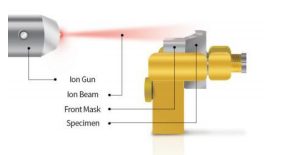

PRINCIPLES OF CROSS CECTION POLISHER

When a voltage is applied to the ion gun and argon gas is injected, plasma is generated and the ion beam is irradiated to the sample by the acceleration voltage to initiate etching.

When the sample is placed behind the metal specimen mask and the ion beam is irradiated to the specimen mask and the sample at the same time, the shielding effect of the specimen mask minimizes the beam damage of the sample, resulting in clean cross-sectional etching.

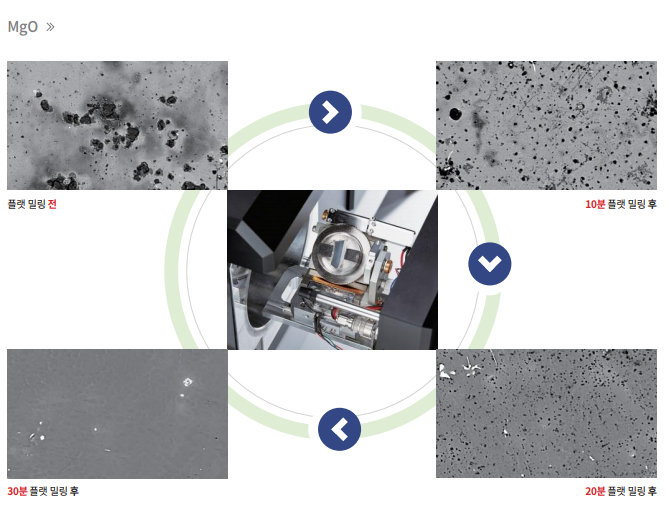

FLAT MILLING

The CP-8000+ can be processed flat using a dedicated holder. When a sample is mounted in a dedicated holder and a flat milling function is used, an area of several mm2 is etched by the ion beam relative to the central axis of rotation. At this time, since the polishing speed, area, and depth vary depending on the angle of incidence of the ion beam hitting the sample surface, uniform surface polishing is performed by adjusting the angle of the sample table and rotating the sample table

| SPECIFICATIONS | |

|---|---|

| Accelerating voltage | 2 to 8kV |

| Milling rate | 700㎛/h (at 8kV on Si wafer) |

| Sample stage swing angle | ±35° |

| Maximum sample size |

20(W) × 10(L) × 5.5(T)mm 16(W) × 10(L) × 9.5(T)mm |

| Specimen movement range | X axis movement : ±3.5mm / Y axis movement : ±2mm |

| Flat milling stage tilt angle range | 40° to 80° |

| Sample size for flat milling | Ø30 × 11.4(H)mm |

| Operation | 7 inch touch panel |

| Digital Microscope for sample positioning | Mag. x5, x10, x20, x40 |

| Chamber camera for monitoring |

Mag. x5, x10, x20, x40 Brightness adjustable in 4 steps Ion beam observation mode (LED Off) |

| Gas for Ion | Argon gas (99.999%) |

| Gas pressure | 0.03 MPa (4.4psi) |

| Gas flow control | Mass Flow Control |

| Vacuum systems | Turbo pump, Diaphragm pump |

| Dimension | 607(W) × 472(D) × 277.5(430.5)(H) mm |

| Weight | Main system 36kg / Diaphragm pump 6.5kg |

| Features |

Auto Beam On/Off mode Step by step mode |

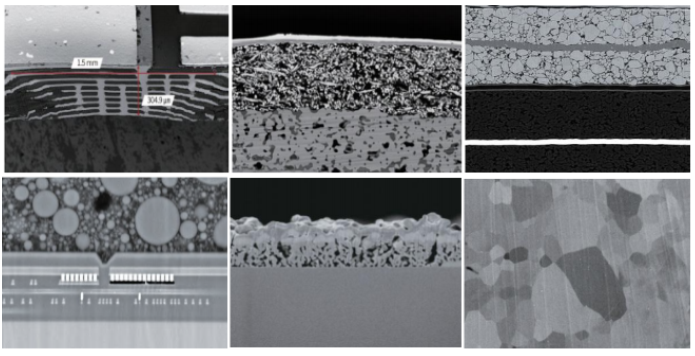

Ion Milling Image