Fill out the analysis request form

Analysis request form

Or phone inquiry

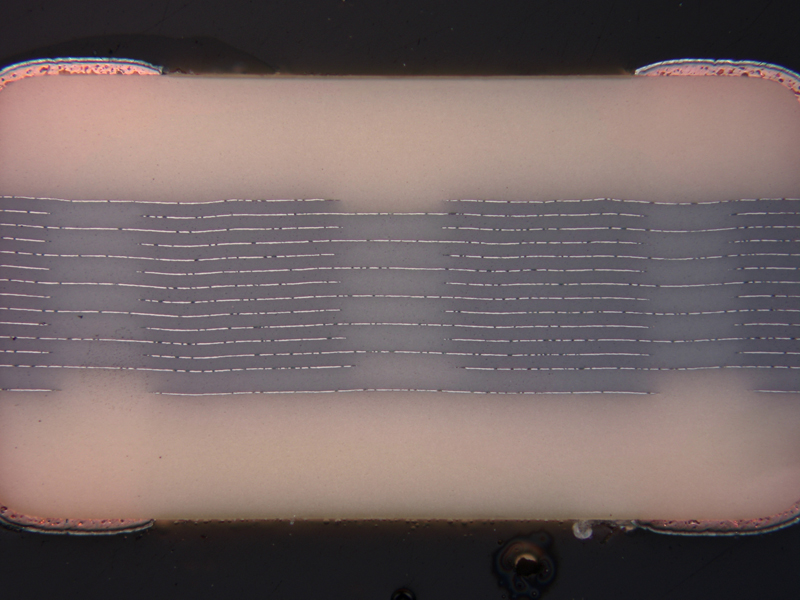

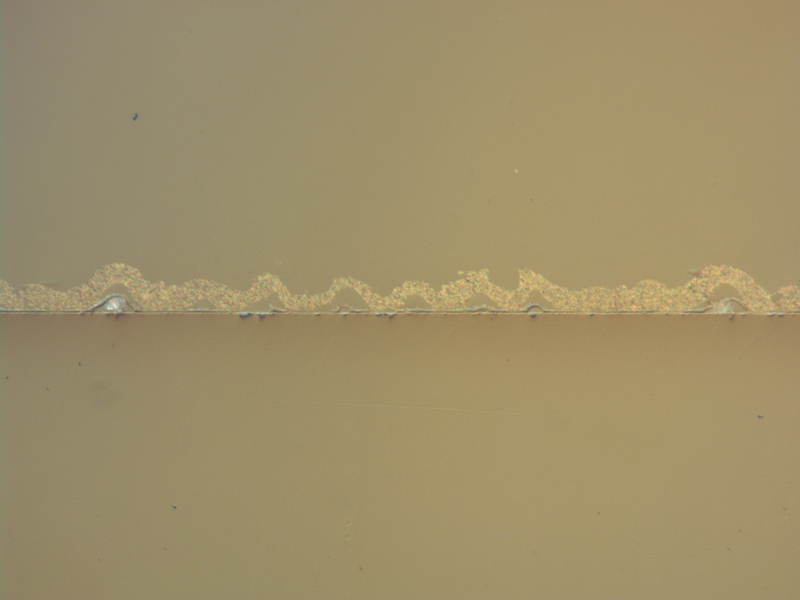

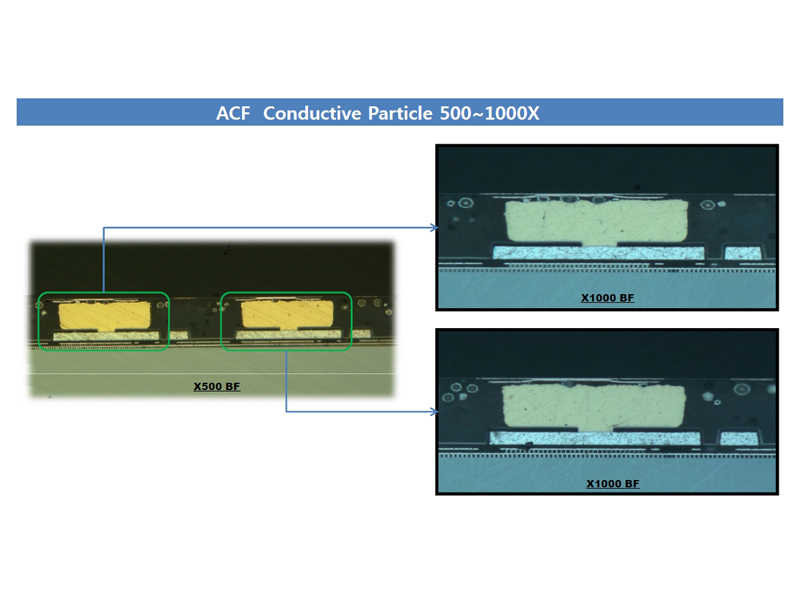

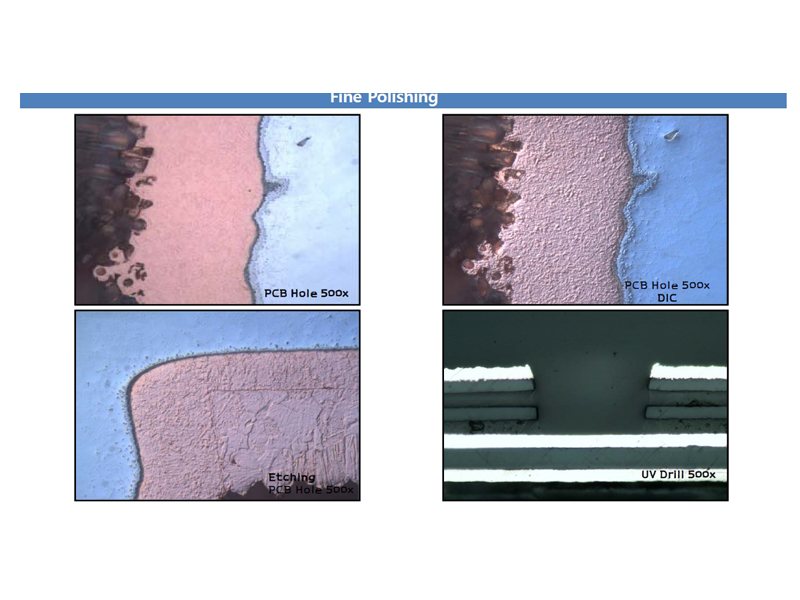

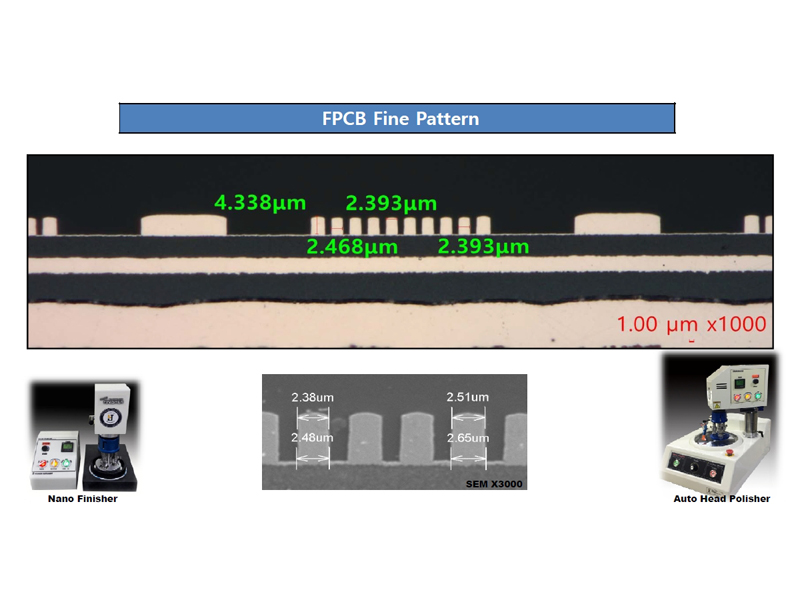

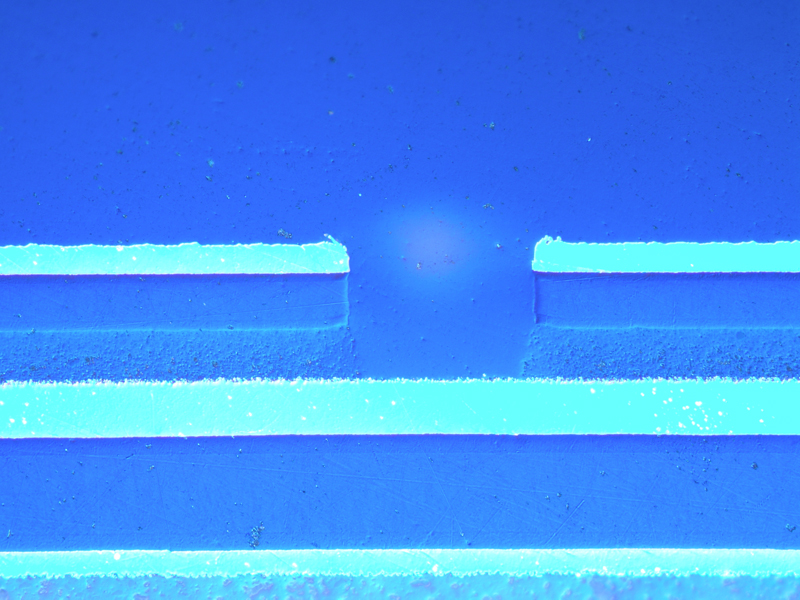

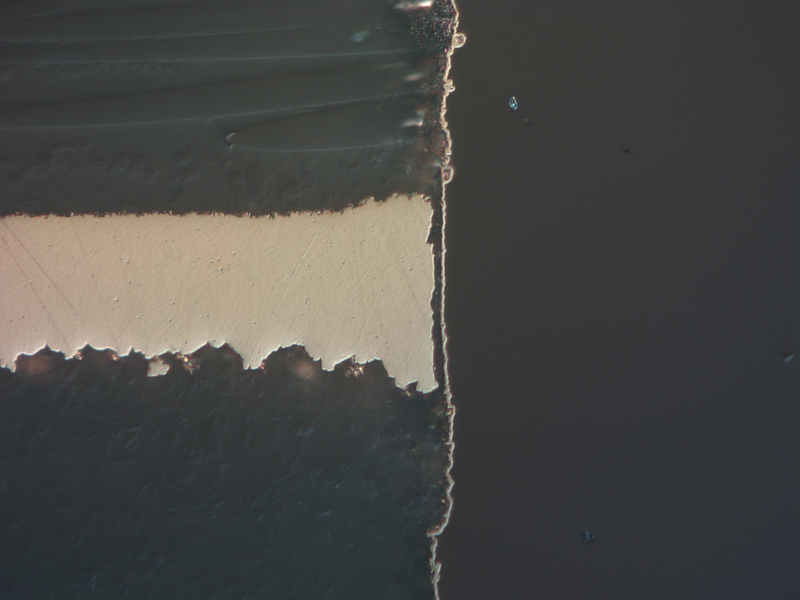

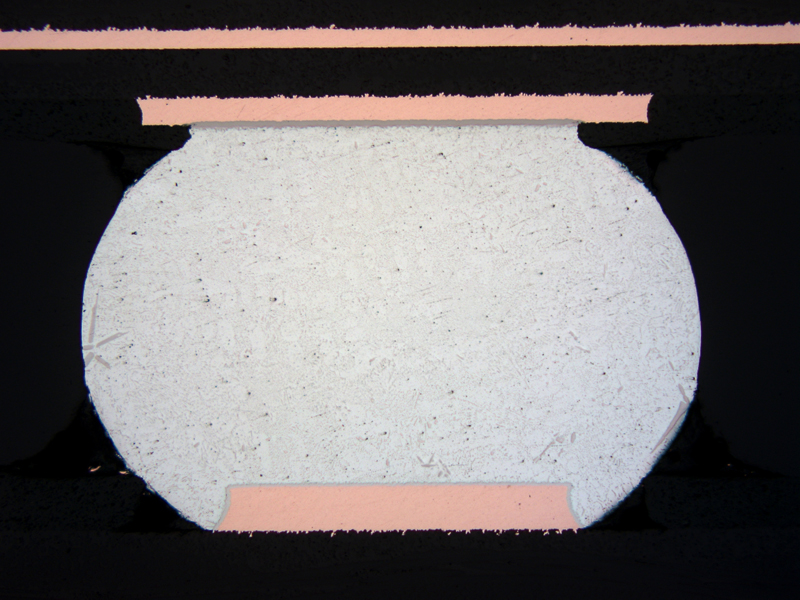

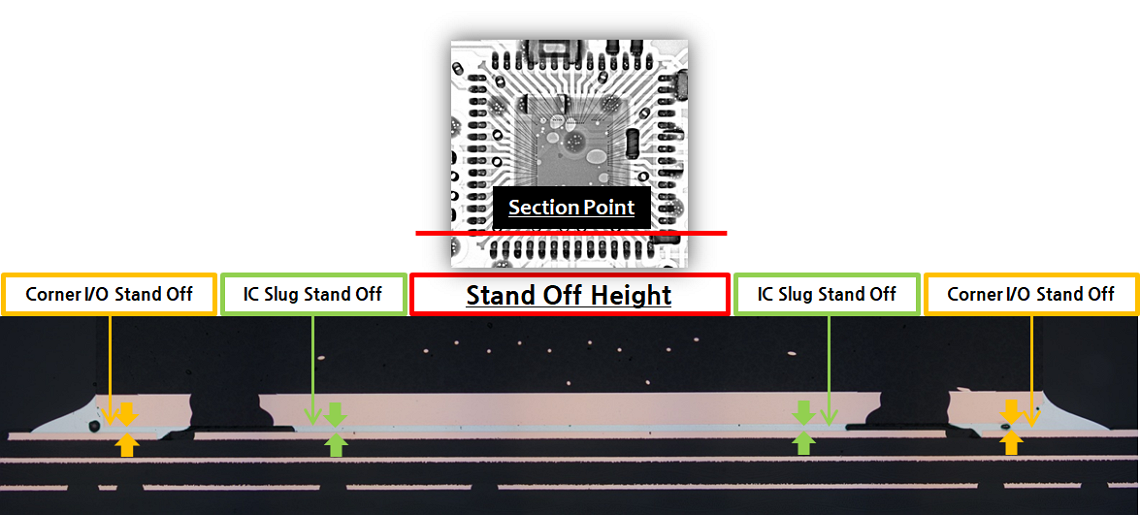

Micro Section is a type of product analysis method, and for accurate analysis, various and sophisticated specimen preparation is required depending on the material, type and characteristics of the sample.

Based on our years of cross-sectional analysis know-how, we apply the appropriate method to each product for accurate results.

We also provide consulting and training on specimen preparation technology for further analysis after analysis.

STEP 1

Analysis request form

Or phone inquiry

STEP 2

Consultation and discussion on the overall direction of the analysis.

STEP 3

Analytical Sample Reception

STEP 4

The process of cutting, molding, grinding, polishing, etc. is carried out by referring to the component, material, size, and characteristics of the sample and considering the effect on the analysis result.

STEP 5

Based on the analysis results, a result report is prepared and delivered to the client.

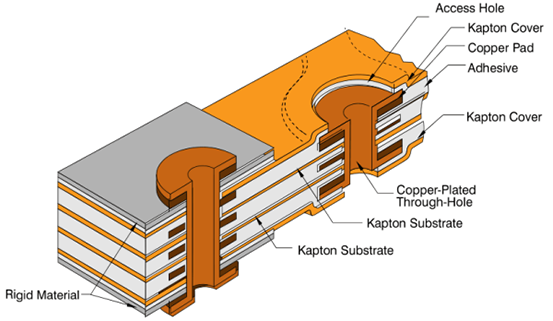

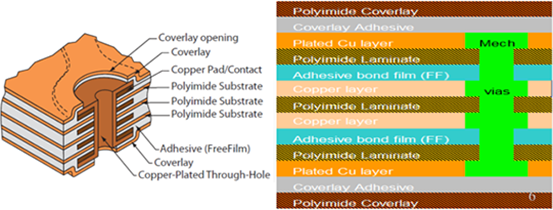

Multi-layer flexible circuits have several layers that are registered to each other and are separated by a cured layer of adhesive during lamination, with interlayer connections via plated-thru holes. Multi-layer is often used in high-speed, impedance controlled requirements and can assist with EMI.

Rigid-flex is the combination of flex circuit and printed circuit board (PCB).